Seguici su:

Primo accesso?

CLICCA QUI

Seguici su:

Primo accesso?

CLICCA QUI

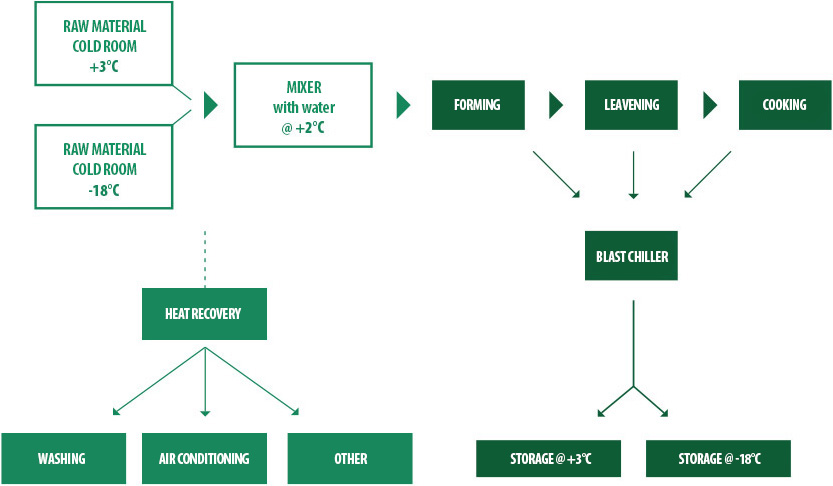

The production process of a cake shop consists of several stages, each with different and specific temperature and humidity requirements:

Tecno Refrigeration is able to develop solutions for each of the stages described, in a view to ensure the quality and reliability required. Through the expertise gained in decades of experience, Tecno Refrigeration offers solutions that are tailored to the specific needs of the customer (in terms of product, temperature, humidity, type of packaging, type of storage, etc.).

The overview of the entire production process and the need for any adjoining rooms is crucial for the simultaneous use of all positive and negative heat flows, which ensures real energy savings: